Corrosion Types - Corrosion Pitting

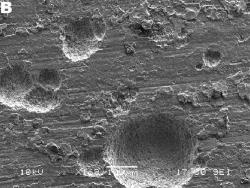

Cavitation Attack

Cavitation Attack

Example of cavitation attack in 440C stainless steel. Application was a pressure vessel, life not known.

Pitting in Aluminum -

Pitting in Aluminum -

The localized pitting corrosionwas produced in aluminum floats on a storage tank roof. The exposure conditions involved hydrocarbon fluids following an initial hydrotest. The pitting occurred in the absence of chlorides at a near neutral pH where aluminum would be expected to exhibit good resistance to corrosion. Sulfur corrosion products were found in the pits and sulfate reducing bacteria were suspected resulting from prolonged exposure to hydrotest water.

CO2 Pitting Corrosion

CO2 Pitting Corrosion

Localized pitting corrosion of steel tubing was observed to occur in a CO2 - oil- water mixture. In this particular case, the flow velocity was very low and the mixture was allowed to separate. Oxygen contamination promoted the localized pitting attack and the low flow rate did not produce adequate mixing for the inhibitor to properly disperse in the water phase

Customer Service & Online QUOTATIONS

VCI SELECTION HELP

Corrosion Blog

TOLL FREE 1-866-577-2326 ONLINE STORE 'We Stop Rust!' TM